Model: 35-35002 35-35112 70-35002 70-35112

Connection: Wafer connection Flange connection

Valve Trim Type: Metal seat,soft seat

Body Type: None: Standard J: Jacket type

35-35002 35-35112 70-35002 70-35112 Pneumatic Camflex valve

Overview

35-35002 35-35112 70-35002 70-35112 Pneumatic Camflex valve is composed of pneumatic actuator and eccentric rotary valve two parts. Pneumatic actuator has two forms, type 35 spring reset drum diaphragm actuator (referred to as drum diaphragm actuator). Eccentric rotating structure is new, a cylindrical body approximation, the center of the spherical valve core and valve spindle rotation center, designed a eccentricity between when rotating valve shaft drives the valve core, valve core sphere relative eccentric rotating body center, the valve core of the soft arm elastic deformation occurs, the spherical valve core and valve seat tightly, to achieve reliable seal, so the valve is also called CAM flexure valve.

Features of 35-35002 35-35112 70-35002 70-35112 Pneumatic Camflex valve

1) Long service life of valve seat. The durable and firm metal or ceramic valve seat sealing ring and eccentric valve core reduce the friction between the valve core and the valve seat, improve the damage of the sealing surface of the valve seat and the resistance during opening and closing, as shown in the left figure. When the valve core rotates to the closed position, the valve core and the valve seat sealing ring will automatically overlap, so that the sealing surfaces can be more reasonably matched. The sealing ring of valve seat can be made of 316 stainless steel, A105 forged carbon steel, surfacing cemented carbide and ceramics. Closed state of eccentric rotary regulating valve

2) Reliable performance. The special valve seat sealing ring design can automatically center, lap and dynamically align with the valve core, which can improve the service life. The sealed metal bearing can prevent the shaft surface of particle accumulation and prevent the valve core from rotating. Opening process of eccentric rotary regulating valve

3) Multiple operations are available. The self centering valve seat sealing ring and solid valve core can achieve sealing when it is used in either direction of forward flow and reverse flow. In the backward flow direction, the outlet turbulent zone is far away from the sealing surface of the valve seat. In addition, the 90 ℃ stroke of the valve core also helps to reduce the scouring between the valve core and the flowing medium and reduce the possibility of damage.

4) Easy installation. The valve body with flange can be connected with different grades of pipe flanges. With different design requirements, exposed flange screws can also be avoided. The positioning surface and overall effect during installation are also good. It can also provide compression type flangeless valve body, which can be positioned by flange screws during installation.

Model compilation and description

Actuator | 35 Rolling Diaphragm Type for Cartridge Reset |

70 Double acting piston | |

Valve series | 35 Eccentric rotary valve |

Installation form of actuator | 1 Parallel pipeline air-close |

2 Parallel duct air-opening | |

3 Vertical pipeline air-close | |

4 Vertical pipeline air-opening | |

5 Parallel pipeline air-close | |

6 Parallel duct air-opening | |

7 Vertical pipeline air-close | |

8 Vertical pipeline air open | |

Valve Trim Type | 1 Metal seat |

2 Soft seat | |

Design series | 2 |

Body Type

| None: Standard J: Jacket type |

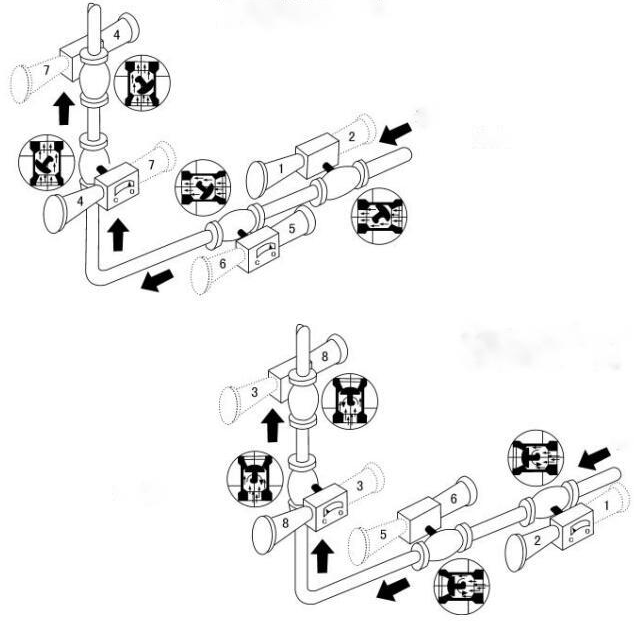

Installation form of actuator

Connection

Standard type

Diameter (inch) | Pressure rating ANSI Class | ||

150 | 300 | 600 | |

1~2 | Wafer connection Flange connection | Wafer connection Flange connection | Wafer connection

|

3~6 | Wafer connection Flange connection | Wafer connection Flange connection | Wafer connection

|

8~12 | Wafer connection | Wafer connection | Wafer connection |

14 | Flange connection | Flange connection | |

Jacketed type

Diameter (inch) | Pressure rating ANSI Class | Connection form and specification with jacket | |

150 | 300 | ||

1*2 1/2 | Wafer connection | Wafer connection | Threaded 1 / 2NPT |

1 1/2*3 | Wafer connection | Wafer connection | Threaded 1 / 2NPT |

2*3 | Flange connection | Flange connection | Flanged 3 / 4 ANSI Class 150 |

3*5 | Flange connection | Flange connection | Flanged 3 / 4 ANSI Class 150 |

4*6 | Flange connection | Flange connection | Flanged 3 / 4 ANSI Class 150 |

6*8 | Flange connection | Flange connection | Flanged 3 / 4 ANSI Class 150 |

Temperature range

Diameter (inch) | Pressure Level ANSI Class | Seat Type | Temperature range | |

Lowest | Highest | |||

1~12 | 150~600 | Metal | -195 | 400 |

150~600 | Soft seat | -73 | 204 | |

14 | 150~300 | Metal | -195 | 400 |

Contact: Andrew Zhang

Phone: 0086-18116465407

E-mail: sales@shanghai-automation.com

Whatsapp:

Add: No.191West Guangzhong Road, Shanghai,P. R.of China 200072

We chat